Cummins Unveils New Generation 2.5L and 3.0L Light-Duty Engines

06 November 2024

This important moment was witnessed by Li Kaiguo, former chairman of the China Automotive Engineering Research Institute and supervisor of the China Society of Automotive Engineers, along with representatives from leading light truck logistics fleets, industry media, and Cummins China and its joint venture teams.

In the context of the country's dual carbon goals, the light truck industry is undergoing a profound transformation in power systems. The sales of new energy light trucks in China continue to rise, and many cities have introduced policies to encourage users to switch to electric light trucks.

However, as a practical tool for production, light trucks are used in a wide range of scenarios, and a single solution cannot meet all demands. In certain applications, diesel power remains advantageous as it is not limited by terrain, weather, or infrastructure and can operate continuously in all conditions. Moreover, in sectors that require high power and reliability, such as frequent starts and stops, acceleration, heavy-load hill climbing, and cold chain transportation that combines driving and refrigeration, diesel-powered light trucks still have a competitive edge.

In this context, Cummins is committed to innovation in traditional energy power systems. Together with its three joint ventures, it has developed the new generation light-duty engine platform, which meets Stage IV fuel consumption regulations, providing low-carbon, high-efficiency power solutions for light truck users.

"Through continuous innovation, diesel-powered light trucks will continue to play an indispensable role for some time to come. Whether addressing the diversification of niche market needs or meeting the specific requirements of regional customers, light-duty diesel engines will continue to hold value across both time and space dimensions," said Li Kaiguo. "With customer demand, companies like Cummins, which are deeply embedded in the market, will continue to invest in R&D and upgrade products, meeting stringent regulatory requirements while achieving lower emissions to meet diverse customer power needs."

Since launching its light-duty engine in the Chinese market in 2009, Cummins light-duty engines have gained widespread trust due to their outstanding performance. Based on its success in the domestic market, Cummins light-duty engines have also expanded to global markets, including Europe and the United States. To date, over 2 million Cummins light-duty four-cylinder diesel engines made in China have been sold globally, winning the trust of OEMs and end users.

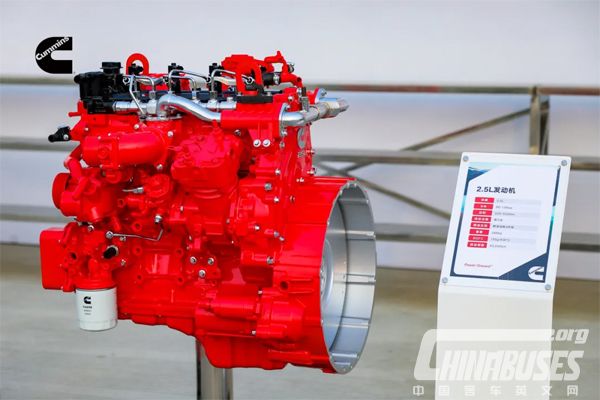

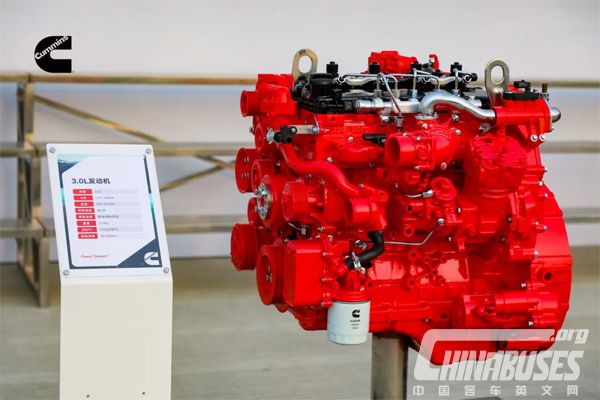

Guided by zero-carbon goals, Cummins has launched the new generation 2.5L and 3.0L light-duty engine platform after three years of development. Based on its FFA2.0 (customized application) strategy and deep market insights, and in collaboration with three domestic OEM partners, the platform integrates the unique technological legacy of Cummins' century-old diesel power systems. The platform offers an excellent balance of fuel efficiency, reliability, durability, economy, and power, providing users with more efficient and long-lasting power solutions.

"With the release of the new generation light-duty platform, Cummins' low-carbon power product line is now more complete, covering products from 2.5L to 15L, all meeting the Fuel Consumption Stage IV standards," said Wang Kaijun. "We firmly believe that good products must withstand market tests. The new generation light-duty engine platform, while maintaining exceptional power and reliability, also achieves a significant improvement in fuel efficiency, bringing customers lower operating costs and greater economic benefits."

Key Features of the New Generation 2.5L and 3.0L Engine Platform

Reliability: The new engines underwent 25,000 hours of bench testing and over 3 million kilometers of vehicle road testing, including rigorous high-temperature, high-altitude, and low-temperature tests. The platform also integrates Cummins' next-generation remote smart service system to enhance uptime with proactive service and remote diagnostics.

Economy: Fuel consumption at the engine level has been reduced by 8%, with potential savings of up to 15% when combined with vehicle-level fuel consumption optimization. The new CBM2.0 technology and IAT intake throttle valve design enable precise control of fuel consumption and improve fuel economy.

Power: The new engines deliver significant improvements in power. The 2.5L engine has 136kW, a 22% increase, and the 3.0L engine has 155kW, a 44% increase. The torque range is broader (1,200rpm to 2,900rpm), offering better transient response for improved start-up, acceleration, and hill-climbing performance.

Additionally, the core components of the new generation 2.5L and 3.0L engines have been fully upgraded, enhancing fuel efficiency and durability.

Cummins Emission Treatment System

The new generation single-tube aftertreatment system is more compact and easier to install in various vehicle models. It features improved SCR conversion efficiency, optimized packaging to reduce backpressure, and new carrier coating technology to enhance low-temperature performance.

Cummins Engine Parts and Software System

The new generation HE150 WG turbocharger is customized for the 2.5L and 3.0L platform, improving efficiency by 5% over the previous generation and enhancing fuel economy. The new design of the turbine blades and housing improves the high-cycle fatigue life by 10%, offering better fuel efficiency and a longer lifespan.

The new generation engines will be installed on light truck models from Foton, JAC, Dongfeng, and FAW, and will be introduced to the market, providing users with more efficient and reliable power solutions.

Source : www.chinabuses.org

Editor : Daisy

Views:18822