Electrified Power System Revealed by Cummins at Busworld Europe

19 October 2017

Cummins proprietary control technology extends the zero-emissions bus range by optimally managing subsystems to maintain a sufficient battery state-of-charge for longer.

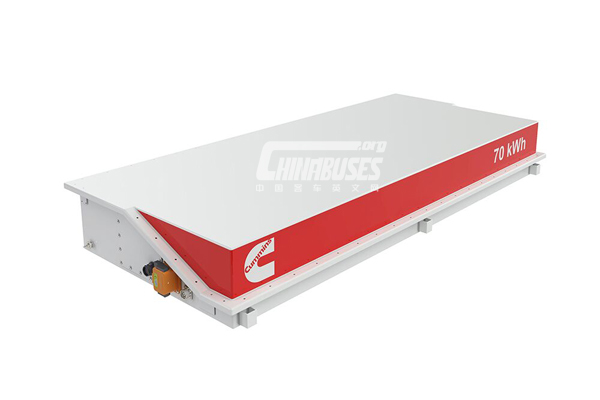

Enhanced energy storage for the BEV and REEV system is achieved with a high-density battery enclosure, designed by Cummins in a compact, modular format for both on-roof and chassis integration into existing bus designs.

Operational flexibility is improved with fast recharge capability using an integral plug-in connection, as well as options for on-route opportunity charging where a pantograph or charge plate infrastructure is available.

“The introduction of our new BEV and REEV systems will complement Cummins clean diesel, natural gas and diesel-hybrid products to offer the broadest, most energy diverse power portfolio — one able to meet the needs of every transit route, every duty cycle and every environmental consideration in Europe on the most cost-effective basis,” said Brian Wilson, Cummins General Manager — Global Bus Business.

The standard-size Cummins battery enclosure provides a 70-kWh storage capability

with up to 8 enclosure units (560-kWh) integrated within the BEV bus. This enables a zero-emissions range of up to 360 km (224 miles) on a single charge, with an energy consumption of just 9 Litres/100 km diesel equivalent (30 mpg) — bringing a major reduction in operating costs.

Cummins 70-kWh Battery Enclosure

Cummins 70-kWh Battery Enclosure

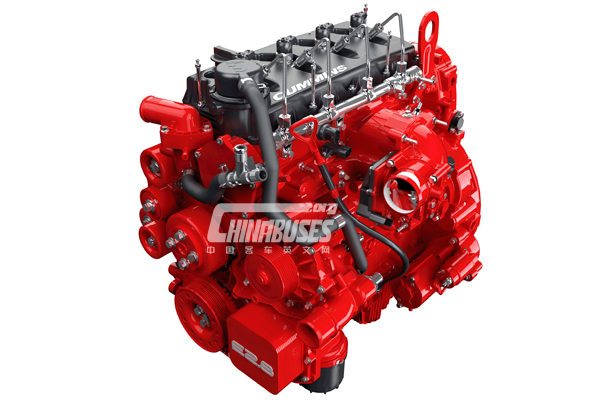

A Cummins REEV system specified with a battery pack of 3 enclosures (210-kWh) provides a zero-emissions range of up to 135 km (84 miles) — a significant advantage over conventional diesel-hybrid bus capability. When the battery pack depletes to a low state-of-charge, the REEV system brings online a 120-kW (160 hp) engine-generator to recharge the batteries and continue operations with ultra-low emissions capability.

The Cummins 2.8-litre engine incorporated with the REEV system represents a 60 percent downsize in displacement compared to engines used in an equivalent diesel bus.

When operating in engine-generator mode, the REEV system achieves a fuel consumption of 18 Litres /100 km (15 mpg) to significantly lower the carbon footprint. A power assist function is available from the battery pack whenever the system needs additional energy.

Cummins 2.8-litre Engine Generator

Cummins 2.8-litre Engine Generator

The ability of the REEV system to switch between shorter-range battery-only mode and extended-range engine-generator mode allows specific areas to be geofenced by utilising Cummins over-the-air connected technology. The REEV system also enables buses to travel significant distances beyond the city charging infrastructure.

“A key focus in the design of both our BEV and REEV systems was to ensure our electrified architecture would be modular and adaptable to enable an easier technology transition for bus manufacturers,” said Julie Furber, Cummins Executive Director - Electrification Business. “This then allows transport authorities to specify the same bus models that work so well for them today and retain fleet commonality.

“The new systems will be expertly serviced by the Cummins distribution network in the same way we currently support our diesel-, hybrid- and natural-gas-powered fleets. This is an important factor for bus operators, as it means seamless support for when they specify our BEV and REEV systems for their fleets.”

Energy Efficiency

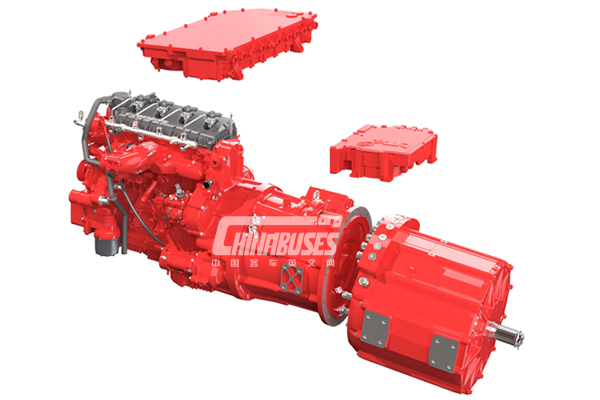

The BEV and REEV systems incorporate the same traction motor and power electronics

to deliver a continuous torque output of 1850 Nm, eliminating the need for gear shifting and dramatically reducing powertrain noise. When the vehicle requires additional tractive power during rapid acceleration or while climbing gradients, the system delivers an instant peak torque boost up to 3400 Nm.

The system provide a continuous electrical output of 225-kW (302 hp), increasing to a peak output of 350-kW (469 hp) whenever a power boost is required. The high-voltage system operates at a nominal 660V when battery state-of-charge is around 50 percent. Battery energy storage levels are boosted on-route by accepting “free” energy recovered

Cummins Range Extended Electrric Vehicle System (REEV)

Cummins Range Extended Electrric Vehicle System (REEV)

through a regenerative braking system. On a frequent stop/start bus duty cycle, this could contribute the equivalent of 20 percent to the battery pack state-of-charge.

Electrical energy is also exportable from the Cummins system to the electric-powered accessories featured on the bus, such as e-power steering, e-HVAC, e-air compressors and e-cooling fans, adding up to a typical 25-kW (33 hp) load at any one time. The electrical supply from the Cummins system can be both low-voltage DC and high-voltage AC, helping to simplify the installation and lower the cost of the e-accessories package.

The same electronic control module used on the popular B4.5, B6.7, L9 and L9N bus engines is adapted for use as the BEV and REEV system controller, offering familiar diagnostics and the connectivity that bus operators experience today. (www.chinabuses.org)

Source : www.chinabuses.org

Views:8353

Tags: Cummins Busworld 2017